Better pixels coming to LCD, OLEDs still not easy to make

Oct 15, 2014

Author: Jeff Yurek

It’s mid-October, IFA’s in the rearview mirror, most of the holiday season products have been announced, and CES looms ahead in January. For those who follow display technology, this is a sort of hot-stove season– a great time to speculate about how everything we saw over the summer will play out in 2015.

At summer shows like DisplayWeek and IFA I saw a clear trend among TV set makers focusing on delivering not just more but better pixels. Pixel enhancing features like high dynamic range, wide color gamut and curved form factors were all big hits at these shows as part of a broader push towards next generation UHD TV.

At the same time there has been a fairly dramatic shift away from OLED technology. Most notably by Samsung, whose flagship IFA demo this year was a giant flexible LCD. This may seem counterintuitive since the idea of better pixels ought to be a win for OLED, a technology that offers great contrast, deep color, and originated the curved craze. So, what gives?

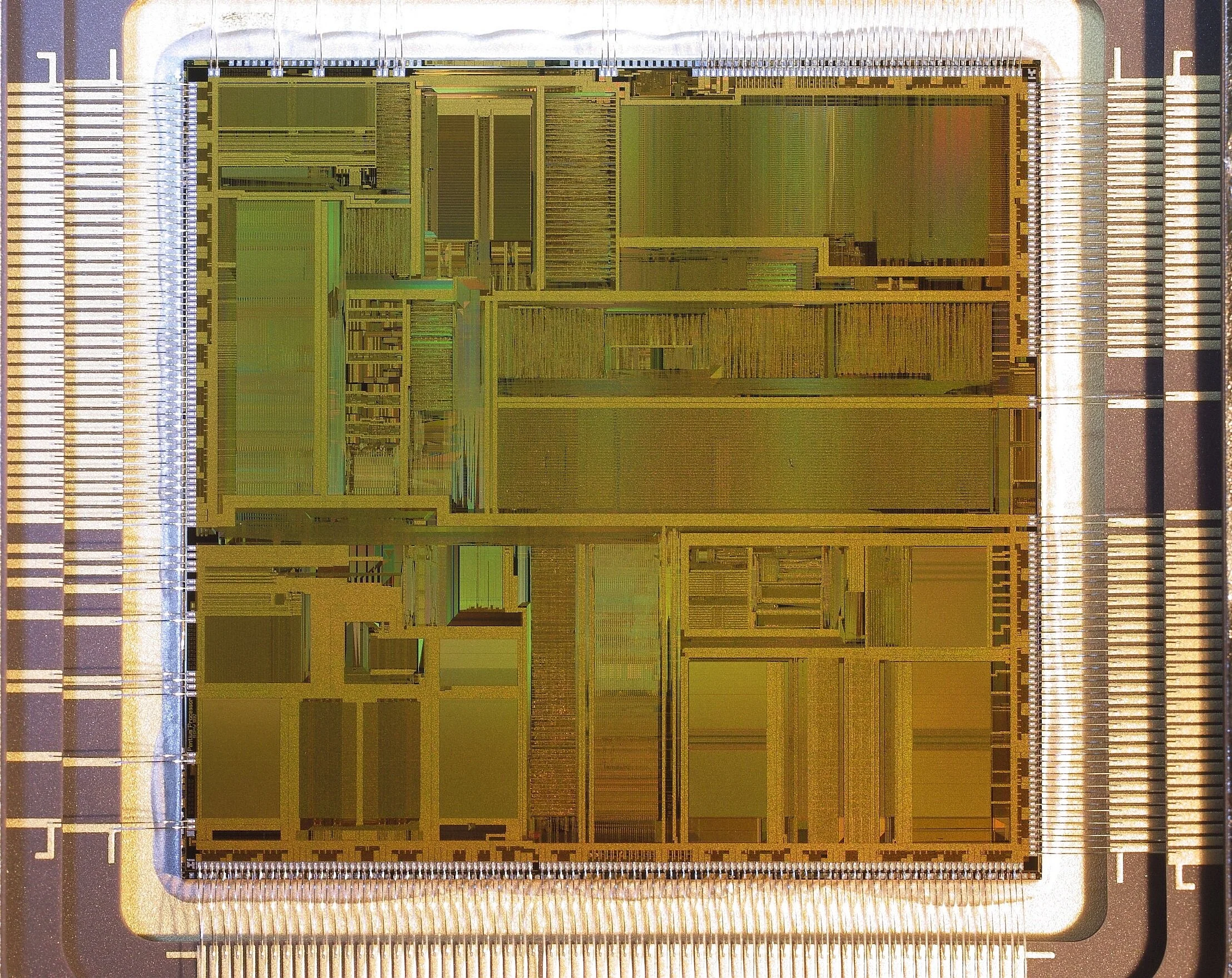

It turns out that large OLEDs are still not easy to make. That’s not exactly news. Just about everyone in the display industry is familiar with the idea that OLEDs have a complex and difficult manufacturing process. In Bob Raikes’ recent piece in DisplayCentral on OLED progress he used a great analogy that underscores the challenges ahead for OLED: “OLEDs are ridiculously difficult to make. OLEDs need four or five times more transistors than LCDs... That means an UltraHD OLED TV has around 40 million transistors – around eight times the number of Intel’s original Pentium chip!”

That’s just a staggering number of extremely high quality transistors to try to manufacture, without defect, on a huge slab of glass. In that sense, it’s truly an achievement that the very best OLED TV manufacturers are now approaching a 70% yield at FHD resolution. As we move to UHD resolutions though the challenges to improve those yields will be enormous. We’re still a long ways away from meaningful cost reduction in OLED manufacturing.

It’s also just really tough to beat LCD. The incumbent display technology has been quick to adopt new technologies that are enabling it to match or beat OLED performance on every front from contrast to color and to do so at much lower costs by leveraging it’s long established supply chain.

With no major breakthroughs on the horizon for OLED we can expect to see a continuation of the IFA TV trends in Las Vegas early next year. LCD makers will continue lead the way, showing off huge UHD LCDs that are loaded with immersive next generation video features and OLEDs will remain relatively scarce in devices larger than a tablet.